SPECIFICATIONS |

| MODE |

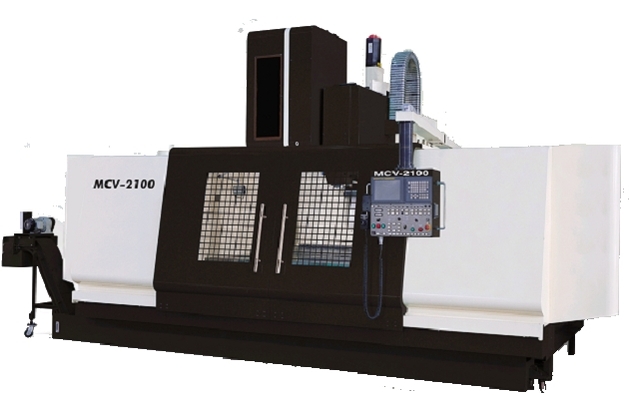

MCV-2100 |

MCV-2600 |

| TABLE |

|

| Working Surface |

2,300 X 970 ( 90.55 X 38.19 ) mm ( inch ) |

2,800 x 970 (110.24 x 38.19) |

| T-Slots ( Size X Number ) |

22 X 5 ( 0.87 X 5 ) mm ( inch ) |

22 x 5 (0.87 x 5) |

| Max. table load |

3,000 ( 6600 ) kg ( lbs ) |

3,000 (6600) |

| TRAVEL |

|

| Longitudinal Travel ( X ) |

2,100 ( 82.68 ) mm ( inch ) |

2,600 (102.36) |

| Cross Travel ( Y ) |

870 ( 34.25 ) mm ( inch ) |

870 (34.25) |

| Headstock Travel ( Z ) |

760 ( 29.92 ) mm ( inch ) |

760 (29.92) |

| Distance Between Spindle End and Table Top |

200 - 960 ( 7.87 - 37.8 ) mm ( inch ) |

200 - 960 (7.87 - 37.8) |

| Distance Between Spindle Center and Column Surloce |

850 ( 33.46 ) mm ( inch ) |

850 (33.46) |

| SPINDLE |

|

| Spindle Nose |

N.T. 50 |

N.T. 50 |

| Spindle Speeds |

4,500 R.P.M. |

4,500 |

| Spindle Speed Ronge |

Two Gears Variable |

Two Gears Variable |

| FEED |

|

| Cutting Feed |

10,000 ( 393.7 ) mm/min ( inch/min ) |

10,000 (393.7) |

| Rapid traverse |

10 / 10 / 8 ( 393.7/ 393.7/ 314.96 ) mm/min ( inch/min ) |

10 / 10 / 8 (393.7 / 393.7 / 314.96) |

| Minimum Input Increment |

0.001 ( 0.0001 ) mm ( inch ) |

0.001 (0.001) |

| ATC ( Automacic Tool Changer ) |

|

| Tool Holder |

BT 50 |

BT 50 |

| Tool Storage Capacity |

32 |

32 |

| Max. Tool Dia. X Length |

110 X 350 ( 4.3 X 13.8 ) ψ X mm ( inch ) |

110 x 350 (4.33 x 17.78) |

| Max. Tool Weight |

15 ( 33 ) kg ( lbs ) |

15 (33) |

| Max. Tool Dia. of adjacent pots are empty |

150 ψ X mm |

150 |

| Tool Selection |

Random |

Random |

| MOTORS |

|

| Spindle Drive Continuous Rating |

15 ( 20 ) Kw ( HP ) |

|

15 (20) |

| Motor Rated Output for 30 Minutes |

18.5 ( 25 ) Kw ( HP ) |

|

18.5 (25) |

| Drive Motors X,Y,Z Axis |

4 (5.4), 4.2 (5.4) , 4.2 (5.6) |

4.2 (5.6) / 4.2 (5.6) / 4.2 (5.6) |

| MACHINE WEIGHT SPACE AND PACKING |

|

| Floor Space |

7,700 X 4,694 ( 303.15 X 184.80 ) mm ( inch ) |

8,600 x 4,694 (338.58 x 184.80) |

| Net Weight |

18,000 ( 39,600 ) Kg ( lbs ) |

19,000 (41,800) |

| |

|

|

| |

|

| STANDARD ACCESSORIES |

SPECIAL ACCESSORIES |

| Heat Exchanger |

Enclosed Splash Guard |

| Removable Manual Pulse Generator |

Flat Type Chip Conveyor & Chip Wagon |

| Coolant Around Spindle |

Rotary Table With 4th Axis Control |

| Spiral Type Chip Conveyor |

4th Axis Connector |

| Semi-enclosed Splash Guard |

Coolant Through Tool |

| RS-232 Interface |

Coolant Through Spindle With Filter |

| Automatic Power Off |

Coolant Wash |

| Call Light |

Automatic Tool Length Measuring Device |

| Automatic Lubrication Equipment |

Automatic Centering Device (Renishaw MP-10) |

| Work Light |

Automatic Pallet Changer |

| Tool Kit |

Cam Mechanism ATC (40 Tools) |

| Spare Fuses |

|

| Pendant Type Operator Panel |

|

| Spindle Cooler |

|

| Rigid Tapping |

|

| |

|

| Specifications are subject to change without prior notice. |