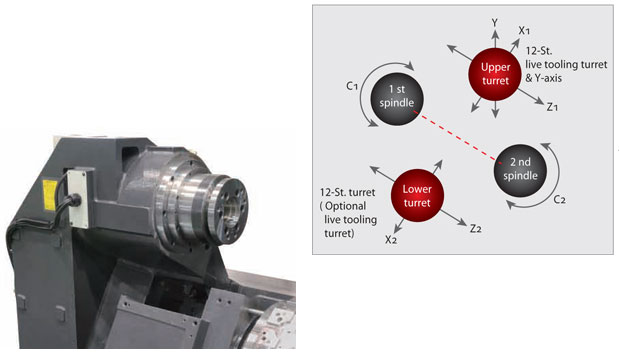

GTS-201 SERIES

TWIN SPINDLES & TURRETS TURNING CENTER

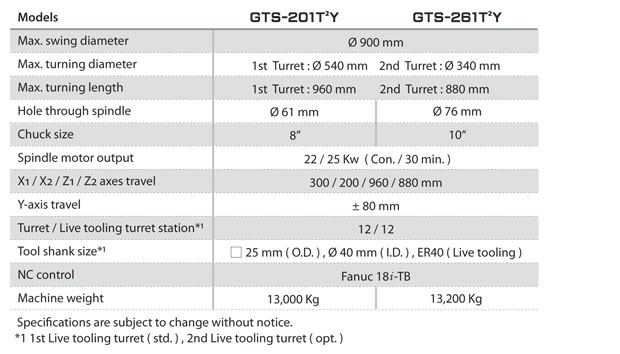

|

|---|

The GTS-201 series is a machine with high efficiency, multi-tasking capabilities. The twin built-in spindles with upper / lower turrets structure gives you high accuracy and excellent balancing of turning power. The upper and lower turret can simultaneously work on the same side of the work piece which saves a tremendous amount of time. It can also be paired with an optional loading / unloading system to save manpower and cycle time for mass production. |

|

|

Casting structure of GTS-201 model shown |

High Performance Live Tooling Turret |

Ø 250 mm diameter super high precision curvic couplings with spindle-driven live tooling turret provides optimum cutting performance. |

High Efficiency Simultaneous Turning |

| With the advanced twin spindles and twin turrets construction, one turret can cut a work piece in one spindle with the other running at the same time. One simultaneous turning machine means replacing two machines which increases working efficiency. |

High Precision Built-in Spindle |

| The main and sub-spindle modules are equipped with cylindrical roller bearings which are better than angular contact bearings. The main spindle is installed with a built-in spindle motor which eliminates power loss and belt slipping problems. The C-axis with high resolution magnetic encoder

provides high precision contour machining capability. |

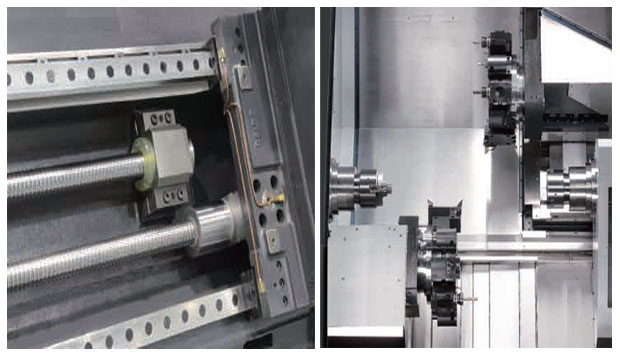

Advanced Slide Way Design |

| The X / Y axes are adopted with high-rigidity, extra-wide box way design to provide solid foundation for heavy-duty cutting. The Z / Zs axes are adopted with high-speed, high-precision roller linear guideway design to increase work piece overall accuracy and maintain excellent cutting rigidity. |

|

|