GS-600 SERIES

POWERFUL TURNING CENTER

|

|---|

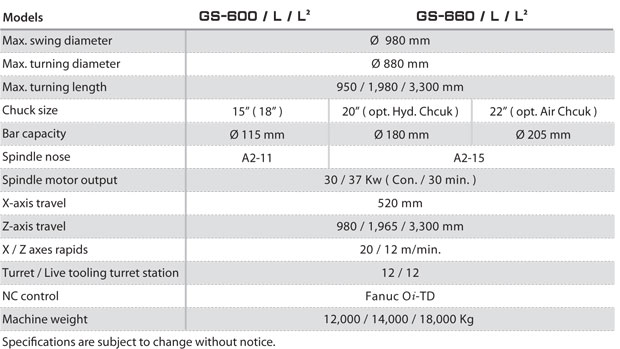

| The GS-600 series is the improved version of the GS-400 series with greater performance and better specifications. These

series combine high torque 2-speed gear heads and large diameter servo indexing turrets with hardened ground box way machine beds and built-in tailstocks to give you heavy-duty cutting capabilities for large-diameter and long

work pieces. Especially suitable for large work piece users in the energy and aerospace industry. |

Major structural components have been combined into one solid platform. The low center of gravity 45° slant bed design provides the most rigid foundation possible for the headstock, turret and tailstock. |

|

Casting structure of GS-600L model shown |

|

|

Optional 12-station Live Tooling Turret |

Ø 450 mm diameter super high precision CURVIC couplings accurately position the turret disk ( ± 2 |

Built-in Type Tailstock |

The built-in bearings quill provide greater rigidity for heavyloads. The extension and retraction of the quill is programmable |

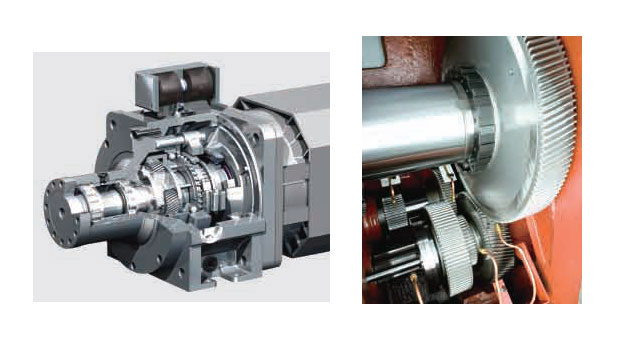

2-speed Gear Box |

| The 2-speed super heavy-duty gear box is driven by a 37 Kw ( Peak ) motor; An optional oil bath German made ZF gear box with 4-speed and 4,912 N-m high torque is also available. |

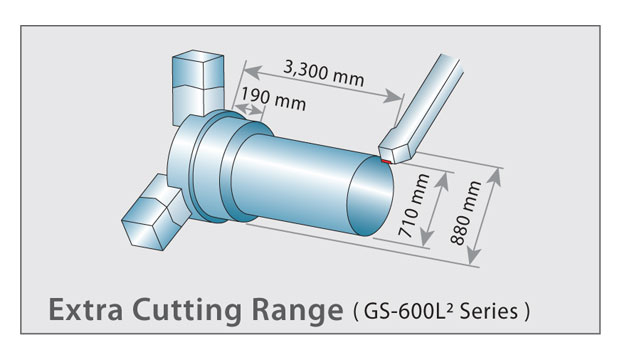

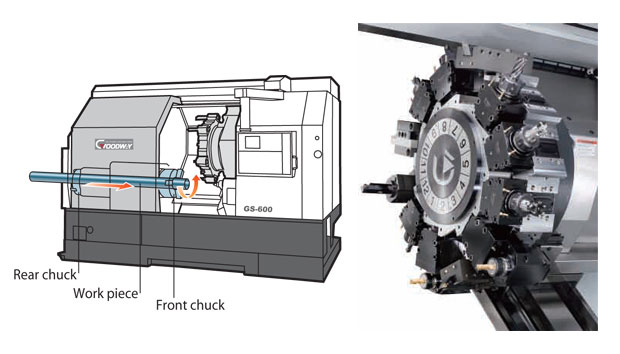

Front + Rear Chuck |

| By installing air or manual chucks on both the front and rear of the spindle, it becomes possible to machine the ends of long workpieces. This configuration is especially useful in threading pipes. |

|

|