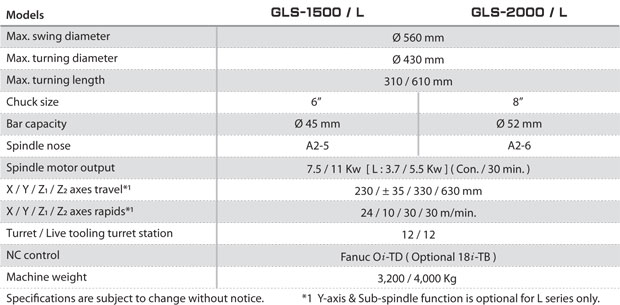

GLS-1500 SERIES - HIGH SPEED TURNING CENTER

|

|---|

| Based on the original GLS-150 series, the all new GLS-1500

series brings a new 30° true slant bed casting design with

lower center of gravity and optional 12-station live tooling

turret ( live tooling tools rotate in working position only ) to

achieve higher rapids and turning speeds. The compact design

and ample functions are able to meet the demanding turning

applications of today and tomorrow. The modern 30° slant bed design provides smooth chip disposal and operator access without sacrificing machining rigidity. X and Z axes are adopted with high-grade linear guideways, providing high speed and high accuracy structural features. |

|

Casting structure of GLS-1500M model shown |

|

|

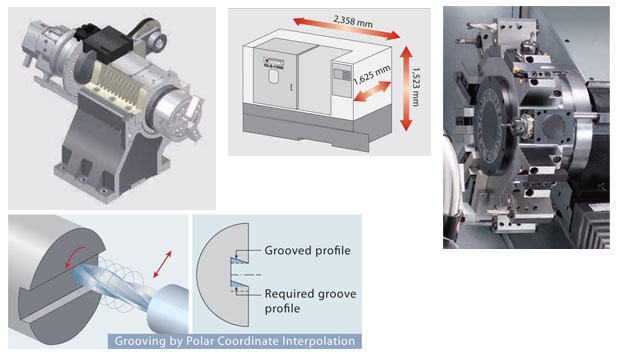

| The new two-piece spindle head

stock is designed with larger heat

dispensing fins to increase

durability for long-term service life. |

Multi-tasking Ability |

| The GLS-1500L series can be equipped with an optional sub-spindle and Y-axis. The sub-spindle is equipped with a 5” chuck with maximum travel up to 630 mm. |

|

| The adjustable pressure tailstock provides greater rigidity and support when cutting longer work pieces. |

Optional 12-station Live Tooling Turret |

The 12-station live tooling turret offers 12 stations available for live tooling. Compact machine design provides you with high speed and high precision capabilities with minimum floor space. |

|