GA SERIES -

HIGH C/P VALUE TURNING CENTER

|

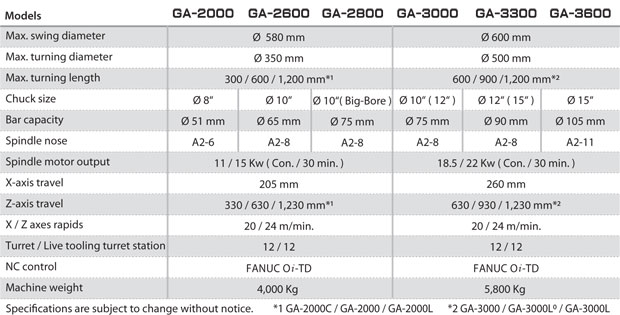

|---|

| For maximum machining capability, the GA-2000 & GA-3000 series machines are built with box-way slides. With 3 sizes of

machine body and bar capacity, most cutting requirements

can be met. The GA-2000C series can be interfaced with gantry

loading system to achieve maximum productivity. The

GA-3000 series with a spindle gear box increases torque in

lower speed turning power. Live tooling turrets are available

for all series of machines. |

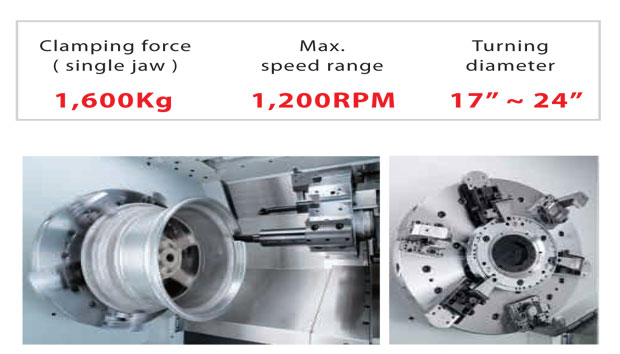

GA-3300/W24 Series Car Rim Turning Center |

| The GA-3300 series equipped with the optional aluminum rim hydraulic chuck turns into a powerful rim processing machine, providing you with maximum strength and wide range working capabilities. |

|

|

GA-3300 / W24 model shown. |

|

|

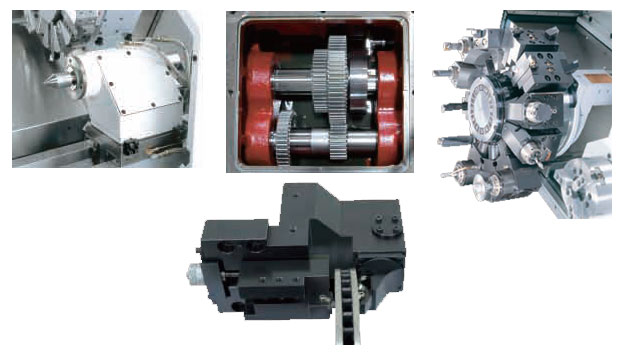

| GA Series machines ( excluding

compact bed C models ) feature a

standard programmable base and

quill tailstock. |

Optional 12-station Live Tooling Turret |

| The 12-station Goodway live tooling turret o ers 12 stations available for live tooling ( live tooling tools rotate in working position only ). |

|

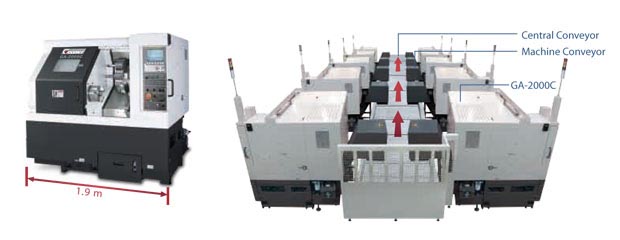

GA-2000C Series Compact Turning Center |

Rear discharge conveyor systems allow machines to be placed closer together, thus, requiring less floor space. Furthermore, all machine conveyors can discharge onto a central conveyor, which carries the chips to one location; this saves man power and streamlines the chip removal process. |

GA-3000 Series GA-2000C Optional Features |

| The optional 2-speed heavy-duty gear

box driven by a 22 Kw ( 30 min. ) motor

provides the GA-3000 series tremendous

amount of low-end torque to handle

heavy material removal on large

diameter parts. Dual-face turning holder allow both sides of a disk-type work piece to be machined at the same time. Tool holder automatically spreads open for retracting tooling to avoid damage to the turned surfaces. |

|